Gabatarwa

Masana'antar kera motoci ta daɗe ta kasance majagaba wajen ɗaukar sabbin fasahohi don haɓaka inganci, daidaito, da ƙima. Daga cikin abubuwan da suka fi dacewa da shi shine firam ɗin abin hawa - ƙashin bayan tsarin da ke tabbatar da aminci, karɓuwa, da aiki. Yayin da buƙatun kayan nauyi, gyare-gyare, da saurin samarwa ke ƙaruwa, masana'antun suna ƙara juyowa zuwa robots na masana'antu don yin juyin juya halin ƙirƙira. Wannan labarin yana bincika yadda injiniyoyin kera ke sake fasalin samar da firam ɗin kera, daga sarrafa kayan aiki zuwa walda da sarrafa inganci, yayin da suke magance ƙalubale da abubuwan da ke faruwa a nan gaba a wannan sashe mai ƙarfi.

Sashi na 1: Muhimman Matsayin Filayen Motoci a Tsararren Mota

Firam ɗin abin hawa, galibi ana kiransa chassis, suna aiki azaman tushe ga duk tsarin kera motoci. Dole ne su jure babban damuwa, shawo kan tasirin karo, kuma su goyi bayan nauyin abin hawa da mazaunanta. An ƙera firam ɗin zamani ta amfani da kayan haɓaka kamar ƙarfe mai ƙarfi, gami da aluminium, har ma da abubuwan haɗin fiber carbon don daidaita ƙarfi tare da rage nauyi.

Koyaya, kera waɗannan hadaddun sifofi na buƙatar madaidaicin daidaito. Ko da ƙananan ƙetare a daidaitawar walda ko haɗa kayan aiki na iya yin illa ga aminci da aiki. Hanyoyin aikin hannu na al'ada suna kokawa don saduwa da tsattsauran haƙuri da ake buƙata ta ƙa'idodin kera motoci na yau, haifar da matsananciyar buƙata ta atomatik.

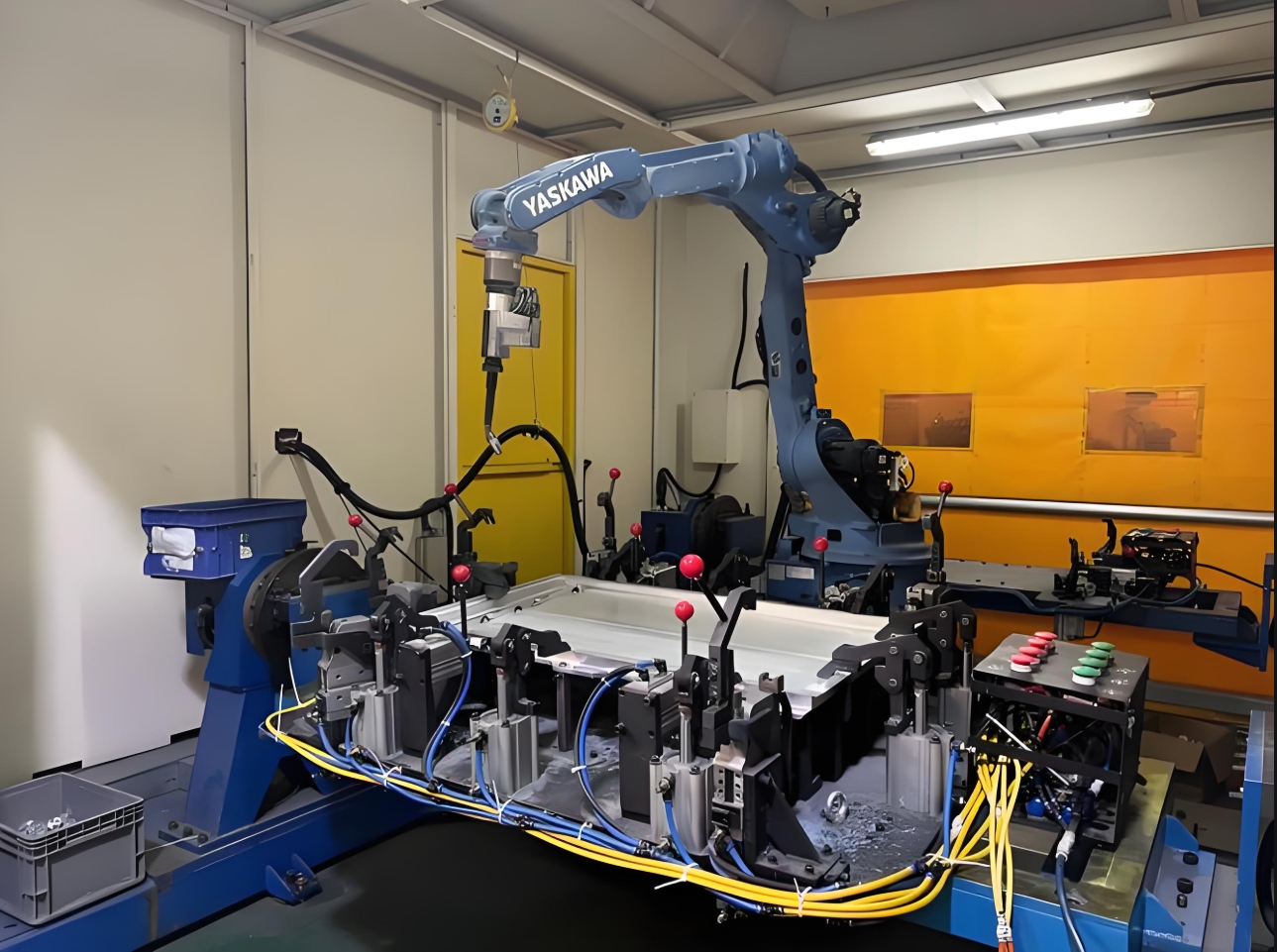

Sashi na 2: Robots Masana'antu a Ƙirƙirar Firam: Maɓallin Aikace-aikace

2.1 Sarrafa kayan aiki da Shirye-shiryen Bangaren

Samar da firam ɗin mota yana farawa da sarrafa albarkatun ƙasa. Robots na masana'antu sanye take da na'urori masu ci gaba da tsarin hangen nesa sun yi fice wajen sarrafa manyan zanen karfe, bututu, da abubuwan da aka riga aka kera. Misali:

- Ƙarfe na takarda: Robots da aka riga an yanke su kuma suna siffata zanen karfe ko aluminum a cikin firam ɗin dogo, maɓalli, da maɓalli tare da daidaiton ƙaramin millimeter.

- Haɗaɗɗen kayan aiki: Robots na haɗin gwiwa (cobots) cikin aminci suna sarrafa nauyi amma abubuwa masu rauni kamar fiber carbon, rage sharar gida da kuskuren ɗan adam.

2.2 Welding da Haɗuwa Fasaha

Welding ya kasance mafi girman matakin da ya dace da mutum-mutumi a masana'antar firam. Tsarin walda na mutum-mutumi na zamani suna isar da daidaito mara misaltuwa a cikin dubunnan wuraren walda:

- Juriya tabo waldi: Multi-axis mutummutumi yi high-gudun tabo waldi a kan karfe Frames, tabbatar da uniform hadin gwiwa ƙarfi.

- Laser walda: Madaidaicin mutum-mutumi masu sanye da kawunan laser suna haifar da haɗin kai maras kyau don firam ɗin aluminium, rage girman murdiya.

- Aikace-aikacen m: Robots suna amfani da adhesives na tsari a cikin sarƙaƙƙiyar alamu don haɗa nau'ikan firam ɗin ƙarfe-ƙarfe, tsari kusan ba zai yuwu a yi kwafi da hannu ba.

Nazarin Harka: Babban mai kera motoci na Turai ya rage lahani na walda da kashi 72% bayan tura rundunar robobi na axis 6 tare da daidaita hanyoyin daidaitawa, masu iya daidaita sigogin walda a ainihin lokacin dangane da ra'ayin firikwensin.

2.3 Taruwa da Haɗin kai

Haɗin firam ɗin ya haɗa da haɗa matakan dakatarwa, madaidaicin injin, da abubuwan aminci. Mutum-mutumi mai hannu bibiyu suna kwaikwayi iyawar ɗan adam don ɗaure kusoshi, shigar da bushings, da daidaita ƙungiyoyin ƙasa da ƙasa. Tsarin jagorar hangen nesa yana tabbatar da an saita abubuwan haɗin gwiwa tsakanin ± 0.1 mm haƙuri, mahimmanci don kiyaye daidaitawar tuƙi.

2.4 Tabbacin Inganci da Tabbataccen Ma'auni

Binciken bayan samarwa yana da mahimmanci don bin ƙa'idodin aminci. Tsarin Robotic yanzu yana aiki:

- 3D Laser scanning: Robots taswirar gabaɗayan firam ɗin geometries don gano warping ko kuskuren girma.

- Gwajin Ultrasonic: Bincike mai sarrafa kansa yana duba amincin walda ba tare da lahani saman ba.

- Gano lahani mai ƙarfin AI: Algorithms na koyon inji suna nazarin ciyarwar kamara don gano ƙananan fashe ko rashin daidaituwa.

Sashi na 3: Fa'idodin Automation na Robotic a Samar da Firam

3.1 Daidaitawa da Maimaituwa

Robots na masana'antu suna kawar da bambancin ɗan adam. Tantanin walda na mutum-mutumi guda ɗaya na iya kiyaye maimaitawar 0.02 mm a cikin kewayon samarwa na 24/7, yana tabbatar da kowane firam ɗin ya dace da ƙayyadaddun ƙira.

3.2 Inganta Tsaron Ma'aikata

Ta hanyar sarrafa ayyuka masu haɗari kamar walda na sama ko ɗagawa mai nauyi, masana'antun sun ba da rahoton raguwar raunin wuraren aiki da kashi 60% dangane da ƙirƙira ƙira.

3.3 Ƙimar Kuɗi

Duk da yake zuba jari na farko yana da mahimmanci, robots suna rage farashi na dogon lokaci ta hanyar:

- 30-50% saurin sake zagayowar lokaci

- 20% ƙananan sharar gida

- Rage 40% na kashe kuɗin sake aiki

3.4 Ƙarfafawa da sassauƙa

Kwayoyin mutum-mutumi na robotic suna ƙyale masana'anta su sake tsara layin samarwa da sauri don sabbin ƙirar firam. Misali, firam ɗin abin hawa na lantarki (EV) tare da rukunan baturi za a iya haɗa su cikin tsarin da ake da su tare da ƙarancin lokaci.

Sashi na 4: Cire Kalubale a Masana'antar Robotic Frame

4.1 Batutuwan Dacewar Abu

Juya zuwa firam ɗin abubuwa da yawa (misali, ƙarfe-aluminum hybrids) yana buƙatar mutummutumi don sarrafa dabarun haɗawa iri ɗaya. Magani sun haɗa da:

- Hybrid waldi shugabannin hada baka da Laser fasahar

- Magnetic grippers don kula da karafa marasa ƙarfe

4.2 Complexity Programming

Software na shirye-shiryen mutum-mutumi na kan layi (OLP) yanzu yana bawa injiniyoyi damar kwaikwaya da haɓaka ayyukan aikin mutum-mutumi ta hanyar lambobi, suna yanke lokacin ƙaddamarwa da kashi 80%.

4.3 Hatsarin Tsaron Yanar Gizo

Kamar yadda samar da firam ɗin ke ƙara haɓaka ta hanyar IoT na Masana'antu, masana'antun dole ne su aiwatar da ka'idojin sadarwar rufaffiyar da sabunta firmware na yau da kullun don kare hanyoyin sadarwar robotic.

Sashi na 5: Makomar Kera Firam ɗin Robotic

5.1 Ƙirƙirar Ƙarfafawar AI-Driven

Robots masu zuwa za su yi amfani da hankali na wucin gadi zuwa:

- Kayan aikin daidaita kai bisa kaurin abu

- Yi tsinkaya da rama kayan aikin lalacewa

- Haɓaka amfani da makamashi yayin buƙatu kololuwa

5.2 Haɗin gwiwar Mutum-Robot

Cobots tare da iyakokin haɗin gwiwa mai ƙarfi za su yi aiki tare da ƙwararrun ƙwararrun gyare-gyaren firam na ƙarshe, tare da haɗa yanke shawarar ɗan adam tare da daidaitaccen mutum-mutumi.

5.3 Samar da Dorewa

Tsarin Robotic zai taka muhimmiyar rawa wajen cimma masana'antar madauwari:

- Ƙarshe ta atomatik na firam ɗin ƙarshen rayuwa don sake amfani da su

- Madaidaicin jigon kayan don rage amfanin albarkatun kasa

Kammalawa

Haɗin robots na masana'antu cikin samar da firam ɗin kera motoci yana wakiltar fiye da ci gaban fasaha kawai-yana nuna babban sauyi kan yadda ake ƙirƙira motoci da gina su. Ta hanyar isar da daidaitattun daidaito, inganci, da daidaitawa, tsarin na'ura na mutum-mutumi yana ƙarfafa masana'antun don biyan buƙatu masu tasowa don mafi aminci, mafi sauƙi, da ƙarin dorewa. Yayin da AI, na'urori masu auna firikwensin ci gaba, da fasahohin kore suka ci gaba da girma, haɗin gwiwa tsakanin injiniyoyin na'ura da injiniyoyin kera motoci babu shakka za su motsa masana'antar zuwa matakan ƙirƙira da ba a taɓa gani ba.

Ga kamfanoni da suka ƙware a cikin injiniyoyin masana'antu, wannan canji yana ba da damammaki masu yawa don yin haɗin gwiwa tare da masu kera motoci don sake fasalta makomar motsi - firam ɗin da aka kera daidai a lokaci guda.

Ƙididdigar Kalma: 1,480

Mabuɗin Sharuɗɗa: Motoci firam ɗin robotics, tsarin walda robotic, AI a cikin masana'anta, robots na haɗin gwiwa, samarwa mai dorewa

Shawarwari na SEO: Haɗe da kwatancen meta da ke niyya "aiki na firam na kera" da "mutumin masana'antu don chassis mota." Yi amfani da hanyoyin haɗin ciki zuwa binciken shari'a masu alaƙa ko shafukan samfur.

Lokacin aikawa: Maris 26-2025