Na farko, hanyar busa iskar gas mai kariya

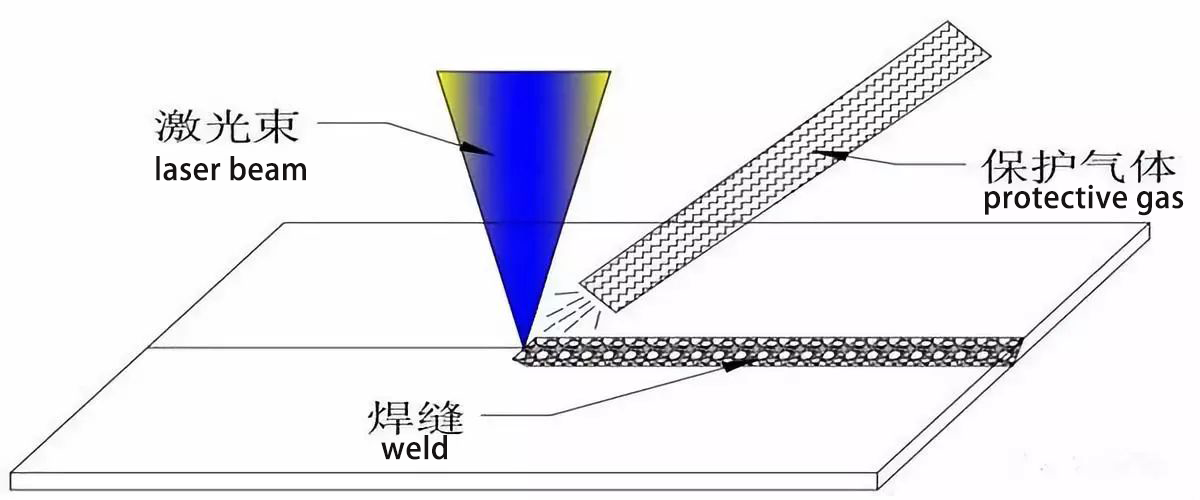

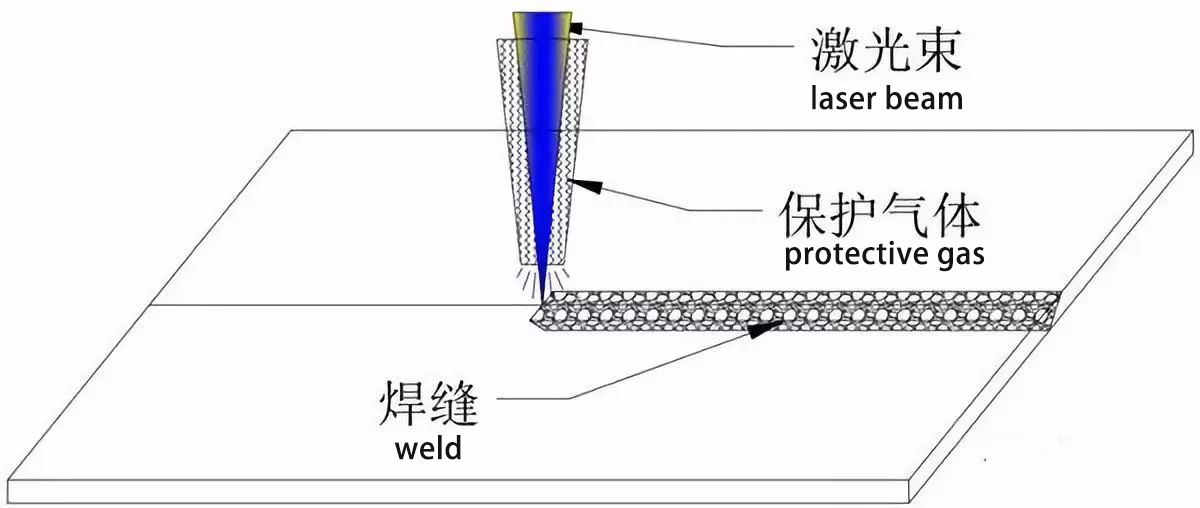

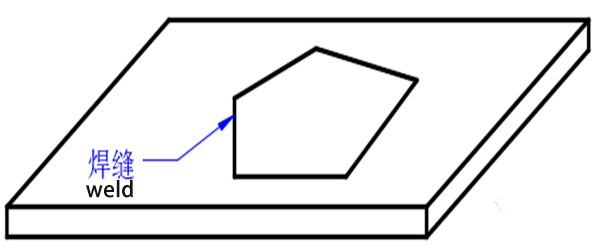

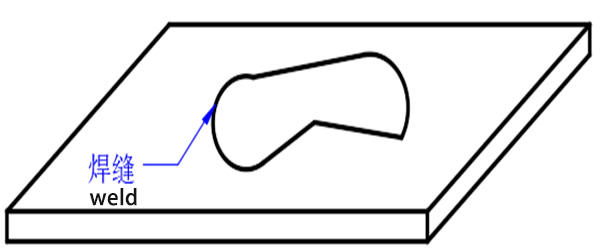

A halin yanzu, akwai manyan hanyoyi guda biyu na busawa na iskar gas: ɗaya iskar gas mai karewa ta gefen gefe, kamar yadda aka nuna a cikin Hoto 1; ɗayan kuma iskar gas ɗin kariya ta coaxial. Ana la'akari da takamaiman zaɓi na hanyoyin busa guda biyu a fannoni da yawa. Gabaɗaya, ana ba da shawarar yin amfani da busa gefe don kare iskar gas

paraxial hura gas kariya

coaxial busa iskar gas mai kariya

coaxial busa iskar gas mai kariyaNa biyu, ka'idar zaɓin yanayin kariyar iskar gas

Na farko, yana buƙatar bayyana cewa abin da ake kira weld shine "oxidized" shine kawai sunan gama gari. A ka’ida, yana nufin halayen sinadaran da ke tsakanin walda da sinadarai masu cutarwa a cikin iska, wanda ke haifar da tabarbarewar ingancin walda. Ya zama ruwan dare ga ƙarfen walda don amsa oxygen, nitrogen da hydrogen a cikin iska a wani yanayin zafi.

Don hana walda daga kasancewa "oxidized" shine don rage ko kauce wa hulɗar irin waɗannan abubuwa masu cutarwa tare da ƙarfe mai walda a cikin yanayin zafi mai zafi. Wannan babban yanayin zafin jiki ba kawai narkakkar pool karfe, amma dukan lokaci tsari daga lokacin da weld karfe ne narke zuwa solidification na pool karfe da kuma zafin jiki ne rage zuwa wani zazzabi a kasa.

Uku, daukar misali.

Alal misali, titanium gami waldi, a lokacin da zafin jiki ne sama da 300 ℃ iya sauri sha hydrogen, fiye da 450 ℃ iya sauri sha oxygen, fiye da 600 ℃ iya sauri sha nitrogen, don haka titanium gami waldi kabu bayan solidification da zazzabi rage zuwa 300 ℃ a kasa wannan mataki bukatar zama tasiri kariya sakamako, in ba haka ba za a "oxidized".

Daga bayanin da ke sama ba shi da wuya a fahimta, kariya daga iskar gas ba kawai buƙatar lokaci don kare walƙiya narke ba, kuma yana buƙatar welded kawai yankin daskararre na kariyar, don haka gabaɗaya paraxial da aka nuna a cikin adadi na 1 gefen gas mai kariya, saboda wannan hanyar dangane da hanyoyin da za a kare kewayon kariya na hanyar kariya ta coaxial na adadi 2 ya fi ko'ina, Esppecially mai ƙarfi don yankin da aka inganta.

Paraxial gefen busa don aikace-aikacen injiniya, ba duk samfuran za su iya amfani da hanyar gefen shaft gefen busa iskar gas ba, don wasu takamaiman samfuran, kawai za su iya amfani da iskar kariya ta coaxial kawai, takamaiman buƙatu daga tsarin samfurin da zaɓin haɗin gwiwa da aka yi niyya.

Hudu, takamaiman zaɓin yanayin busa iskar kariya

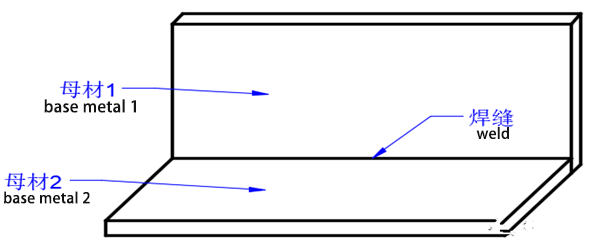

1. Madaidaicin walda

Kamar yadda aka nuna a cikin Hoto 3, sifar weld na samfurin shine madaidaiciyar layi, kuma nau'in haɗin gwiwa na iya zama haɗin gwiwa na butt, haɗin gwiwa na cinya, haɗin gwiwa mara kyau ko haɗin haɗaɗɗen walda. Don irin wannan nau'in samfurin, yana da kyau a ɗauki hanyar gefen shaft ɗin busa iskar gas kamar yadda aka nuna a hoto 1.

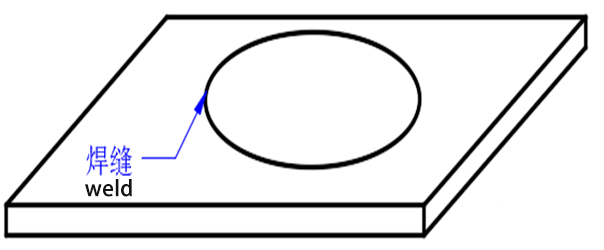

2. Lebur rufaffiyar hoto weld

Kamar yadda aka nuna a Hoto na 4, sifar weld ɗin samfurin shine sifar dawafi na jirgin sama, siffa mai yawa na jirgin sama, siffar layi mai nau'i-nau'i da yawa da sauran sifofin rufaffiyar. Siffofin haɗin gwiwa na iya zama haɗin gwiwa na gindi, haɗin gwiwa, haɗin walda mai rufi da sauransu. Don irin wannan samfurin, yana da kyau a ɗauki yanayin iskar gas na coaxial wanda aka nuna a cikin Hoto 2.

Zaɓin iskar gas mai karewa kai tsaye yana shafar ingancin walda, inganci da farashin samarwa, amma saboda bambancin kayan walda, a cikin ainihin aikin walda, zaɓin iskar gas ya fi rikitarwa, yana buƙatar cikakken la'akari da kayan walda, hanyar walda, matsayi na walda, kazalika da buƙatun tasirin walda, ta hanyar samun sakamako mai kyau na walƙiya don zaɓar mafi kyawun walda.

Source: Fasahar walda

Lokacin aikawa: Satumba-02-2021