Gabatarwa

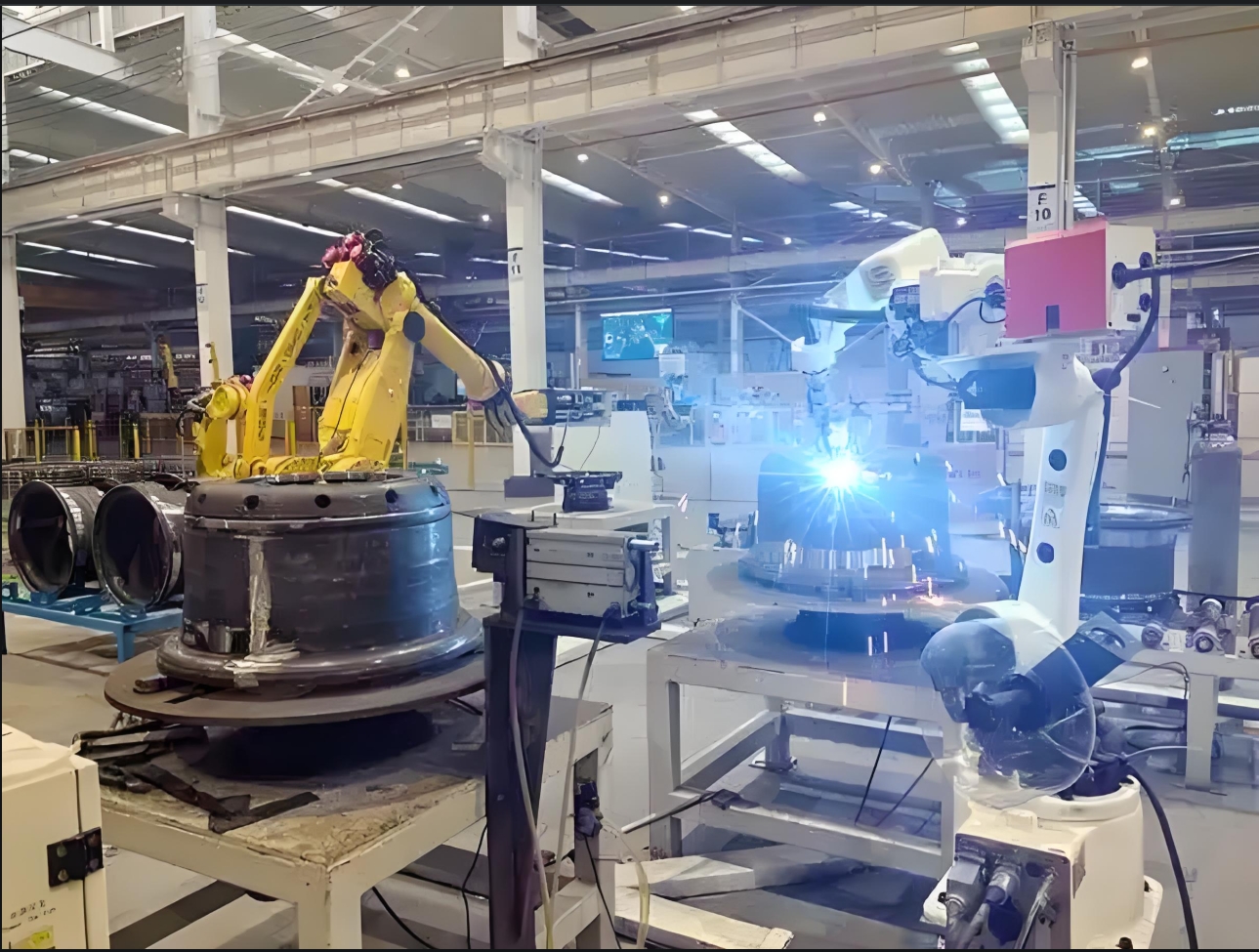

Bangaren kera motoci yana ƙara dogaro da robobin masana'antu don cimma daidaito, inganci, da daidaito wajen samarwa. Daga cikin mafi mahimmanci aikace-aikace shine walda na kayan aikin mota, musammanaxles(kuma aka sani daabin hawa axleskoaxles mota), waɗanda ke da mahimmanci don kwanciyar hankali na abin hawa, watsa wutar lantarki, da ɗaukar kaya. Wannan labarin ya bincika yadda ci gabatsarin walda na mutum-mutumisuna yin juyin juya hali na samar da axles da sauran sassa na mota, yayin da suke nuna manyan kalmomi a cikin dukakayan aikin motakumakayan aikin walda.

Sashi na 1: Maɓallin Abubuwan Kayan Aiki a Mayar da hankali

Kera mota ta ƙunshi rikitattun taruka, tare da abubuwan da ke biyowa suna da mahimmanci don aikin abin hawa. Anan gamanyan kalmomi 5 na kayan aikin motadangane da wannan tattaunawa:

- Axle (Axle Mota/Axle Mota)

Axles sune tsakiya ga titin abin hawa, haɗa ƙafafun da goyan bayan nauyin abin hawa. Daidaitaccen walda yana tabbatar da daidaiton tsari da karko. - Tsarukan dakatarwa

Abubuwan da aka haɗa kamar makamai masu sarrafawa da struts suna buƙatar walƙiya mai ƙarfi don jure wahalar hanya. - Abubuwan Drivetrain

Sassan kamar gidaje daban-daban da ɗumbin watsawa sun dogara da walda masu ƙarfi. - Frames na Chassis

Kashin bayan abin hawa, firam ɗin chassis yana buƙatar daidaitaccen ingancin walda don aminci. - Ƙarfafa Tsarukan

Hadadden welds akan manifolds da bututu dole ne su yi tsayayya da zafi da lalata.

Daga cikin wadannan,waldi na axleya yi fice saboda ƙwarewar fasaha da tasiri akan aikin abin hawa.

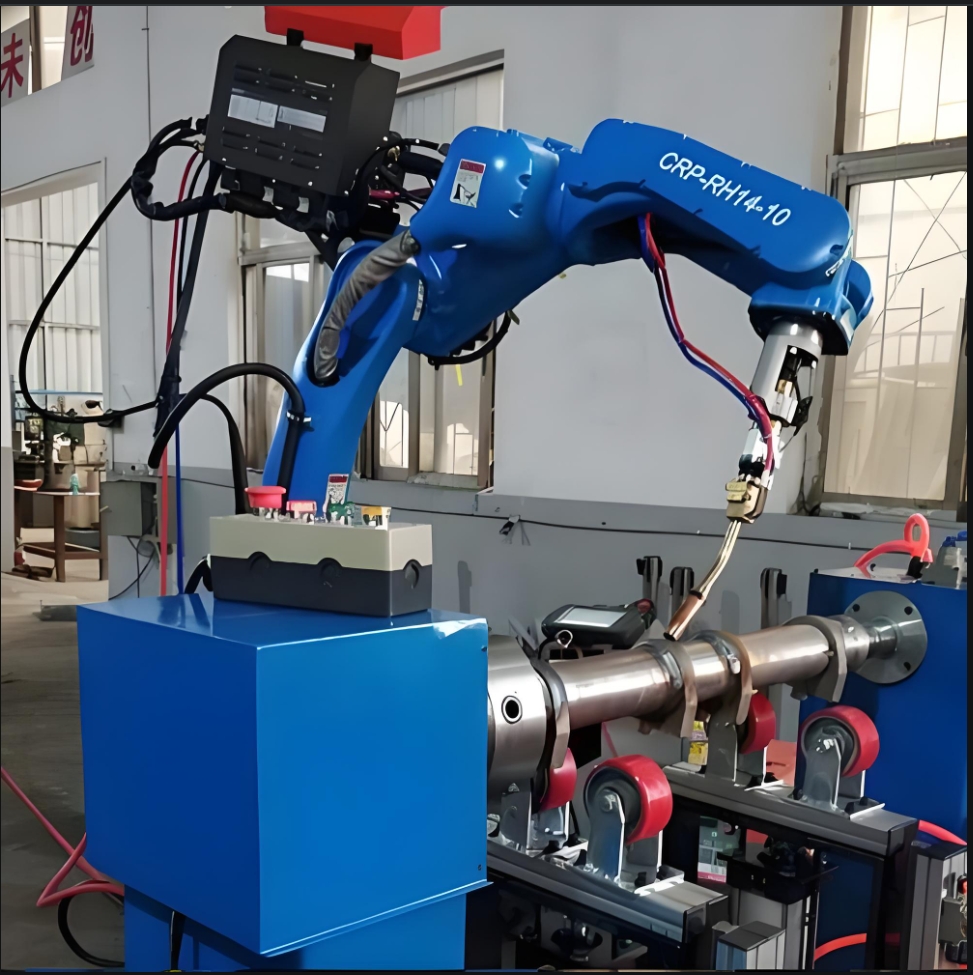

Sashi na 2: Robots Welding Masana'antu: Fasaha da Ƙarfi

Na zamanitsarin walda na mutum-mutumihaɗa fasahohin ci-gaba don saduwa da ƙa'idodin mota. A ƙasa akwaitop 5 walda robot keywords:

- Welding mai sarrafa kansa

Automation yana tabbatar da maimaitawa kuma yana rage kuskuren ɗan adam a cikin samar da girma mai girma. - Arc Welding (MIG/TIG)

An fi so don ƙirƙira axle saboda zurfin shigar ciki da ƙaƙƙarfan samuwar haɗin gwiwa. - Laser Welding

Ana amfani da shi don ayyuka masu madaidaici, kamar walda bakin bakin gatari tare da ɗan murdiya. - Spot Welding

Mafi dacewa don haɗuwa da zanen ƙarfe masu rufi a cikin dakatarwa ko abubuwan haɗin chassis. - Robots na Haɗin gwiwa (Cobots)

Haɓaka sassauƙa a cikin mahalli na samarwa, aiki tare da masu fasaha.

Waɗannan fasahohin suna ba da damar masana'antun su cimmawaldi mara lahaniakan abubuwa masu mahimmanci kamar axles.

Sashi na 3: Welding Axles tare da Robots Masana'antu: Tsari da Fa'idodi

Mataki 1: Zane da Shirye-shiryen

Axle walda yana farawa da simintin CAD/CAM don inganta hanyoyin walda. Robots an tsara su don motsi masu axis masu yawa, suna tabbatar da samun damar yin amfani da rikitattun geometries.

Mataki na 2: Shirye-shiryen Kayan aiki

Axles yawanci ana yin su ne daga ƙarfe mai ƙarfi ko aluminum gami. Tsarin na'ura mai ba da hanya tsakanin hanyoyin sadarwa yana share fage da matse sassa don rage rashin daidaituwa.

Mataki 3: Kisa Welding

- Arc Welding: Ana amfani dashi don gidaje masu kauri mai kauri, yana tabbatar da zurfi, sutura iri ɗaya.

- Laser Welding: Aiwatar da daidaitattun haɗin gwiwa a cikin ƙirar axle mara nauyi.

- Sensors na Bibiyar Seam: rama rashin daidaiton kayan abu a ainihin lokacin.

Fa'idodin Robotic Axle Welding:

- Ingantattun Ƙarfi: Daidaitaccen walda yana rage raunin rauni.

- Saurin Zagayowar Lokaci: Robots suna aiki 24/7, haɓaka fitarwa.

- Tashin Kuɗi: Rage yawan tarkace da rage farashin aiki.

- Tsaro: Yana kawar da tartsatsi da hayaƙi ga ma'aikata.

Sashi na 4: Yanayin Masana'antu Yana Siffata Walƙar Robotic

- Ikon Ingantaccen Ƙarfin AI

Algorithms na koyon inji suna nazarin amincin weld, suna nuna lahani a ainihin lokacin. - Buƙatun Sauƙaƙe

Robots sun dace da kayan haɓakawa na ci gaba kamar abubuwan haɗin aluminum-carbon don axles na abin hawa na lantarki (EV). - Haɗin kai na IoT

Robots masu wayo suna watsa bayanan aiki zuwa tsarin tsakiya don kiyaye tsinkaya. - Dorewa

Hanyoyin walda masu amfani da makamashi suna rage sawun carbon.

Wadannan matsayi matsayitsarin walda na mutum-mutumikamar yadda babu makawa a cikin masana'antar kera motoci na zamani.

Sashi na 5: Kalubale da Magani

Duk da yake waldawar mutum-mutumi tana ba da fa'idodi masu yawa, ƙalubale sun ci gaba:

- Babban Zuba Jari na Farko: Ragewar ROI na dogon lokaci daga karuwar yawan aiki.

- Complex Programming: Sauƙaƙe ta hanyar mu'amala mai sauƙin amfani da kayan aikin kwaikwayo na layi.

- Canjin kayan abu: Adireshi tare da na'urori masu daidaitawa da gyare-gyaren AI.

Don waldawar axle, haɗin gwiwa tare da gogaggunmasana'antar robot masana'antuyana tabbatar da dacewa mafita.

Kammalawa

Walda na kayan aikin mota kamar axles yana misalta ikon canzawa narobots masana'antu. Ta hanyar amfaniwaldi mai sarrafa kansa,arc waldi, kumawaldi na Laserfasahohi, masana'antun sun cimma daidaito da inganci mara misaltuwa. Kamar yadda masana'antar kera ke haɓaka-musamman tare da haɓakar EVs-tsarin walda na mutum-mutumizai kasance tsakiyar samar da ɗorewa, kayan aiki masu inganci. Ga 'yan kasuwa da ke neman sabunta hanyoyin samar da su, saka hannun jari a cikin injiniyoyi na zamani na walda ba kawai zaɓi bane amma larura.

Mahimman kalmomi: Axle, Motar Axle, Tsarukan Dakatarwa, Kayan Aikin Mota, Frames Chassis; Welding mai sarrafa kansa, Tsarin walda na Robotic, Welding Arc, Welding Laser, Spot Welding.

Lokacin aikawa: Afrilu-02-2025