Masana'antar kera motoci iri ɗaya ce tare da ƙirƙira, mai buƙatar daidaito mara ƙarfi, saurin gudu, da dogaro a masana'anta. Daga cikin mahimman sassa na kera motoci, tsarin shaye-shaye—musamman bututun shaye-shaye—suna taka muhimmiyar rawa wajen aikin abin hawa, sarrafa hayaki, da rage hayaniya. Kamar yadda masana'antun ke ƙoƙarin cimma ƙaƙƙarfan ƙa'idodin inganci da maƙasudin samarwa, robobin walda sun bayyana a matsayin kayan aikin da babu makawa wajen ƙirƙira na'urorin shaye-shaye. Wannan labarin ya bincika yadda tsarin walda na mutum-mutumi, wanda aka haɗa tare da kayan sakawa na ci gaba kamarRotary karkatar matsayikumakayan aiki na musamman, suna jujjuya samar da bututun shaye-shaye na motoci, haɓaka inganci, daidaito, da ingancin samfur zuwa matakan da ba a taɓa gani ba.

1. Matsalolin Samar da bututun da ake fitarwa

Ana fuskantar matsanancin yanayi na bututun fitar da hayaki, gami da yanayin zafi mai zafi, iskar gas mai lalata, da girgizar injina. Don jure wa waɗannan ƙalubalen, yawanci ana ƙirƙira su ne daga bakin ƙarfe ko alumini na ƙarfe kuma suna buƙatar walda mara ƙarfi, mara iska a cikin hadadden geometries. Hanyoyin walda na gargajiya na al'ada galibi suna gwagwarmaya don kiyaye daidaito a cikin irin waɗannan aikace-aikacen, wanda ke haifar da lahani kamar porosity, rashin cika fuska, ko murdiya.

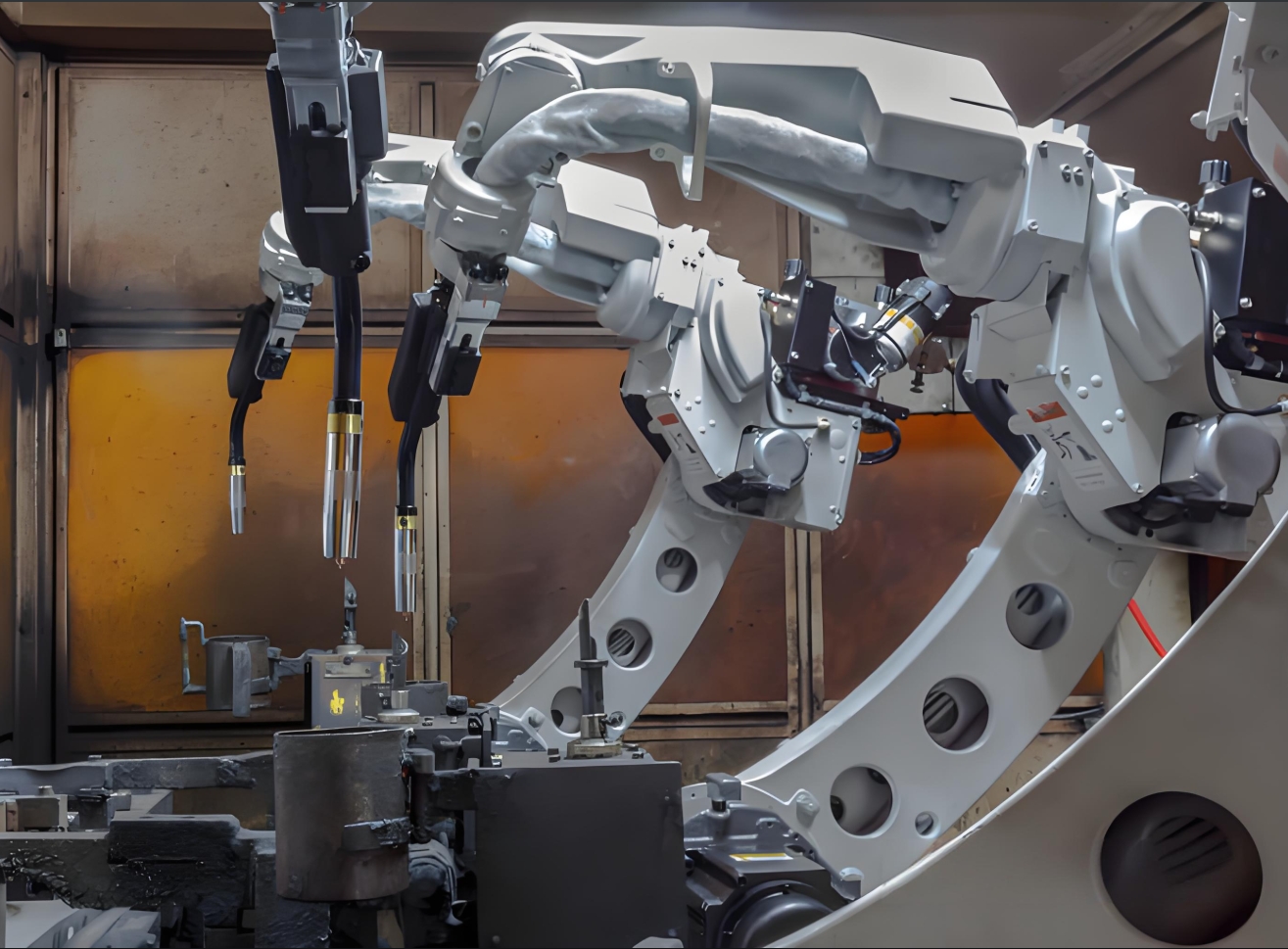

Robots ɗin walda, duk da haka, sun yi fice wajen sarrafa waɗannan sarƙaƙƙiya. An sanye shi da fasahar axis da yawa kuma ana aiki tare tare da daidaitattun tsarin sakawa, suna isar da welds marasa aibu akan filaye masu lanƙwasa, flanges, da haɗin gwiwa-mahimmanci don tabbatar da amincin tsarin shaye-shaye.

2. Robotic Welding a Action: Key Applications for Exhaust Pipes

2.1 Tube-zuwa-Flange da Tube-zuwa-Muffler Welding

Tsarukan ƙyalewar sun ƙunshi abubuwa da yawa, gami da bututu, masu canza motsi, resonators, da mufflers. Na'urorin walda na Robotic suna sarrafa haɗa bututu zuwa flanges ko gidajen muffler, suna tabbatar da shigar iri ɗaya da kuma rage yankunan da zafi ya shafa (HAZ). Misali, a6-axis articulated robotzai iya kewaya kewayen bututu, yana kiyaye kusurwoyi mafi kyau na tocila da saurin tafiye-tafiye har ma a kan filaye da aka ƙera.

2.2 Laser Welding don Abubuwan Kayayyakin Kayayyakin Sirri

Bututun shaye-shaye na zamani galibi suna nuna ƙirar sirara mai bango don rage nauyi yayin kiyaye ƙarfi. Robots ɗin walda na Laser, tare da ƙarfin ƙarfinsu da kunkuntar walda, suna hana warping da adana kayan abu. Wannan yana da fa'ida musamman ga tsarin shaye-shaye na bakin karfe, inda daidaito yake da mahimmanci.

2.3 Welding Multi-Pass don Haɗuwa Masu Kauri

Don na'urorin shaye-shaye masu nauyi a cikin motocin kasuwanci, tsarin walda na iskar gas na ƙarfe (GMAW) yana aiwatar da walda masu wucewa da yawa don gina ƙaƙƙarfan haɗin gwiwa tsakanin bututu masu kauri da maɓalli. Algorithms na walda masu daidaitawa suna daidaita sigogi a ainihin lokacin don ɗaukar bambancin kayan aiki.

3. Haɓaka sassauƙa tare da Rotary Tilt Positioners

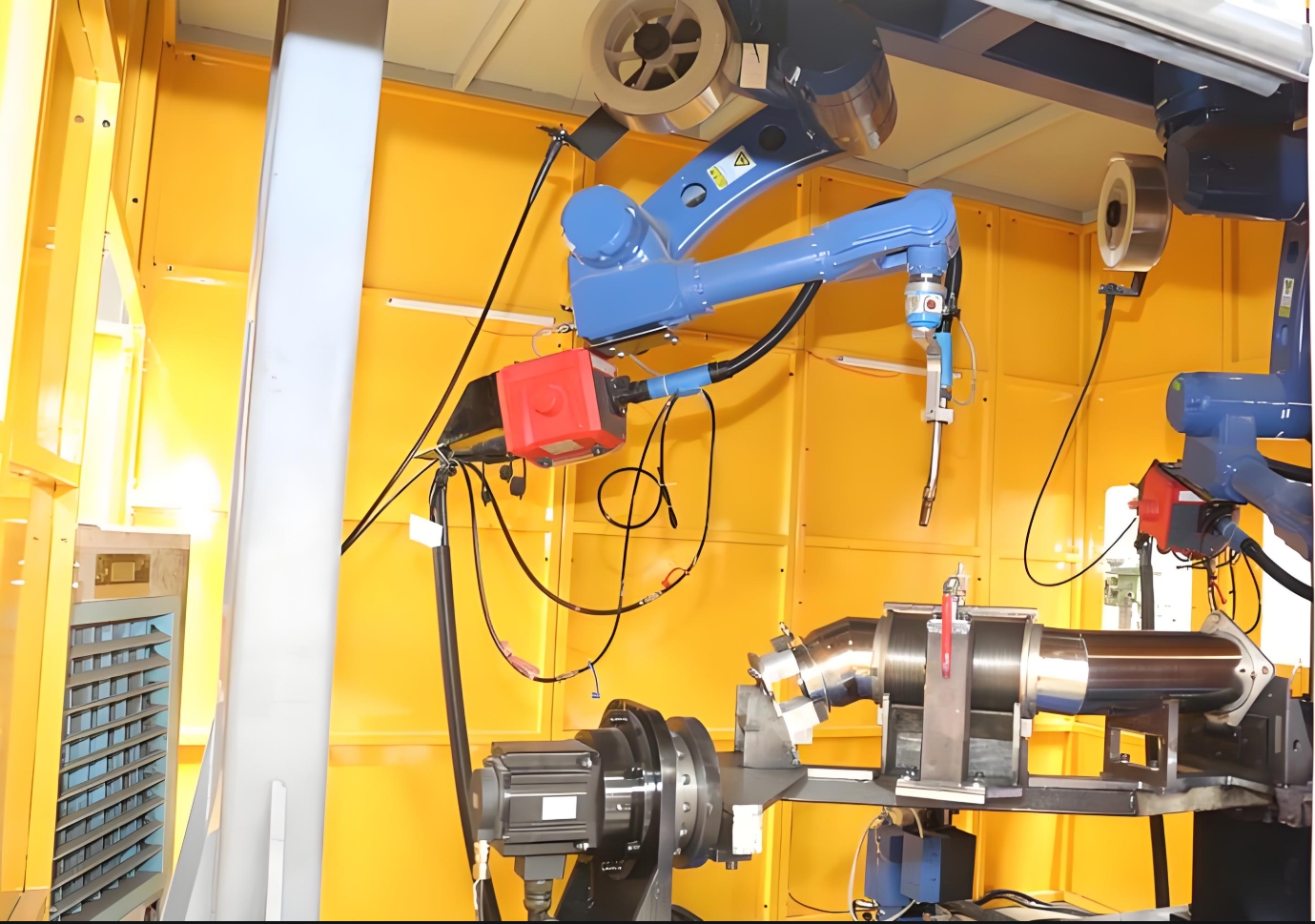

Ingantacciyar cell ɗin walda ta mutum-mutumi yana rataye akan daidaitawa mara kyau tsakanin mutum-mutumi da kayan aiki.Rotary karkatar matsayiSuna da mahimmanci a cikin wannan tsari, suna ba da damar juyawa-digiri 360 da karkatar da bututun shaye-shaye yayin walda. Amfanin sun haɗa da:

- Mafi kyawun Samun Haɗin gwiwa: The positioner reorients bututu don gabatar da weld dinki a cikin lebur ko a kwance matsayi, sauƙaƙa robot shirye-shirye da kuma rage sake zagayowar sau.

- Rage Matsawa: Ta hanyar daidaita kayan aikin, mutum-mutumi na iya kammala walda da yawa a saiti ɗaya, yana rage lokacin aiki.

- Ingantattun Ergonomics: Masu aiki suna ɗora / sauke kayan aiki yayin da mutum-mutumi yana walƙiya, yana ƙara yawan abin da ake samu.

Misali, madaidaicin tasha biyu yana ba da damar walda bututu ɗaya yayin da ake loda na gaba, yana samun ci gaba da samarwa.

4. Daidaitaccen Daidaitawa: Ƙashin Ƙaƙwalwar Daidaitawa

Musammankayan waldasuna da mahimmanci don riƙe abubuwan shaye-shaye daidai daidai lokacin waldawar mutum-mutumi. Mahimman abubuwan ƙira sun haɗa da:

- Dabarun Matsala: Makullin huhu ko na'ura mai aiki da karfin ruwa amintacce bututu, flanges, da braket ba tare da tabarbarewar saman ba.

- Modularity: Canje-canje masu saurin canzawa suna ɗaukar nau'ikan diamita na bututu ko daidaitawa, manufa don samar da samfuran gauraye.

- Gudanar da thermal: Kayan gyaran gyare-gyaren da aka yi daga kayan da ke da zafi suna jure wa tsayin daka zuwa ga baka na walda.

Na'urori masu ci gaba suna haɗa na'urori masu auna firikwensin don tabbatar da jeri na sassa kafin fara walda, kawar da lahani.

5. Ƙididdiga Ingantaccen Riba

Amincewa da tsarin walda na mutum-mutumi a cikin masana'antar bututun shaye-shaye yana ba da ƙarin ci gaba mai ma'ana:

- Rage Lokacin Zagayowar: Na'urar walda ta MIG na mutum-mutumi na iya kammala walƙiyar dawafi a cikin daƙiƙa 60, idan aka kwatanta da daƙiƙa 180+ don waldar hannu.

- Mafi Girma Uptime: Robots suna aiki 24/7 tare da ƙarancin ƙarancin lokaci, yana haɓaka fitowar shekara ta 30-50%.

- Tattalin Arziki: Madaidaicin ma'auni yana rage spatter da sake yin aiki, rage farashin kayan amfani da 15-20%.

Misali, mai siyar da motoci Tier-1 ya ruwaito a40% karuwa a cikin kayan aikibayan tura sel mutum-mutumi tare da madaidaicin matsayi don taron shaye-shaye.

6. Haɓaka inganci zuwa Matsayin Motoci

Robotic walda yana tabbatar da bin ka'idodin ingancin mota kamar IATF 16949:

- Maimaituwa: Robots suna maimaita hanyoyin walda tare da daidaiton ± 0.1 mm, kawar da bambancin ɗan adam.

- Gano Lalacewar: Haɗin tsarin hangen nesa ko na'urori masu saka idanu na baka suna gano rashin daidaituwa a tsakiyar tsari, yana haifar da gyare-gyare nan da nan.

- Takaddun bayanaiNa'urori masu sarrafa kansu suna haifar da rajistan ayyukan walda, mai mahimmanci don dubawa da tunowa.

Binciken bayan walda ya nuna cewa tsarin mutum-mutumi yana rage porosity da fashewa sama da 90% idan aka kwatanta da hanyoyin hannu.

7. Dorewa da Yanayin Gaba

Masu kera motoci suna ƙara ba da fifiko ga dorewa. Robotic walda yana goyan bayan wannan motsi ta:

- Rage Amfani da Makamashi: Ingantattun baka-kan lokaci da ingantattun hanyoyin motsi ƙananan amfani da wutar lantarki.

- Rage Sharar gida: Ƙimar farko-farko mafi girma yawan yawan amfanin ƙasa yana rage raguwa.

- Ƙaddamar da Haske mai nauyi: Daidaitaccen walda yana sauƙaƙe amfani da ci gaba, kayan da ba su da ƙarfi ba tare da lahani ba.

Kallon gaba,Mutum-mutumin walda da AIzai ba da damar koyon injin don haɓaka sigogi don sabbin kayan aiki, yayin darobots na haɗin gwiwa (cobots)zai taimaka masu aiki a cikin ƙananan samar da kayayyaki.

Kammalawa

A cikin babban mahimmin tsarin kera motocin haya, robobin walda—wanda aka haɓaka ta masu sakawa masu hankali da na'urori - suna wakiltar kololuwar ingantattun injiniyoyi. Ta hanyar sarrafa hadaddun ayyukan walda, waɗannan tsarin suna ƙarfafa masana'antun don cimma lokutan zagayowar sauri, inganci mara kyau, da samarwa mai ƙima. Yayin da ka'idojin fitar da iskar shaye-shaye ke takurawa kuma ƙirar abin hawa ke tasowa, fasahar walda ta mutum-mutumi za ta kasance ginshiƙan ƙirƙira, tare da fitar da masana'antar kera motoci zuwa ga mafi wayo, tsaftar makoma.

Ga masu kera robobin masana'antu, jaddada waɗannan iyawar a aikace-aikacen bututun mai ba wai kawai yana nuna ƙwarewar fasaha ba har ma suna sanya hanyoyin magance su azaman abokan haɗin gwiwa masu mahimmanci don haɓaka haɓaka masana'antar kera motoci.

Lokacin aikawa: Maris 21-2025