Robot waldi na TIG

Gabatarwar Samfur

An fi amfani da GTAW don walda sassan bakin karfe na bakin karfe da karafa maras tafe kamar aluminum, magnesium, da gami da jan karfe. Tsarin yana baiwa ma'aikaci iko mafi girma akan walda fiye da matakai masu fafatawa kamar walda na baka na ƙarfe mai kariya da waldar baka na gas, yana ba da damar samun ƙarfi, mafi inganci welds. Koyaya, GTAW ya fi rikitarwa kuma yana da wahalar ƙwarewa, kuma ƙari, yana da hankali sosai fiye da sauran dabarun walda. Wani tsari mai alaƙa, walda baka na plasma, yana amfani da fitilar walda ta ɗan ɗan bambanta don ƙirƙirar baka walda mafi mai da hankali kuma a sakamakon haka galibi ana sarrafa shi.

Yunhua na amfani da matakan kariya na musamman a lokacin walda na TIG, kuma za a yi wani littafi na musamman don ma'aikaci, kawai idan ma'aikacin zai iya bin littafin, kuma ya yi sau da yawa, za a iya sarrafa shi cikin sauri.

KYAUTATA KYAUTA & BAYANI

| Samfura | Saukewa: WSM-315R | Saukewa: WSM-400R | Saukewa: WSM-500R | |

| Ƙididdigar shigarwar ƙarfin lantarki / mitar | Mataki na uku380V (+/-) 10% 50Hz | |||

| Ƙarfin shigar da ƙima (KVA) | 11.2 | 17.1 | 23.7 | |

| Ƙididdigar shigarwa na halin yanzu (A) | 17 | 26 | 36 | |

| Ƙimar dorewar lodi (%) | 60 | 60 | 60 | |

| DC da kuma m halin yanzu | Welding Curren (A) | 5-315 | 5-400 | 5-500 |

| DC bugun jini | Mafi girman halin yanzu (A) | 5-315 | 5-400 | 5-500 |

| Base current (A) | 5-315 | 5-400 | 5-500 | |

| Pulse Duty (%) | 1 ~ 100 | 1 ~ 100 | 1 ~ 100 | |

| Mitar bugun jini (Hz) | 0.2-20 | |||

| TIG | Arc farawa a halin yanzu (A) | 10-160 | 10-160 | 10-160 |

| Arc stop current (A) | 5-315 | 5-400 | 5-500 | |

| Lokacin haɓakawa na yanzu (S) | 0.1 ~ 10 | |||

| Lokacin rage-rage (S) | 0.1-15 | |||

| Lokacin Pre-flow (S) | 0.1-15 | |||

| Lagging lokaci na dakatar da iskar gas (S) | 0.1-20 | |||

| Salon aiki na baka na dakatar da halin yanzu | Mataki Biyu, Mataki Hudu | |||

| TIG matukin jirgi arc salon | HF baka | |||

| Hannun baka walda walda halin yanzu | 30-315 | 40-400 | 50-500 | |

| Yanayin sanyaya | Ruwa sanyaya | |||

| Shell kariya daraja | 1P2S | |||

| Matsayin rufi | H/B | |||

Aikace-aikace

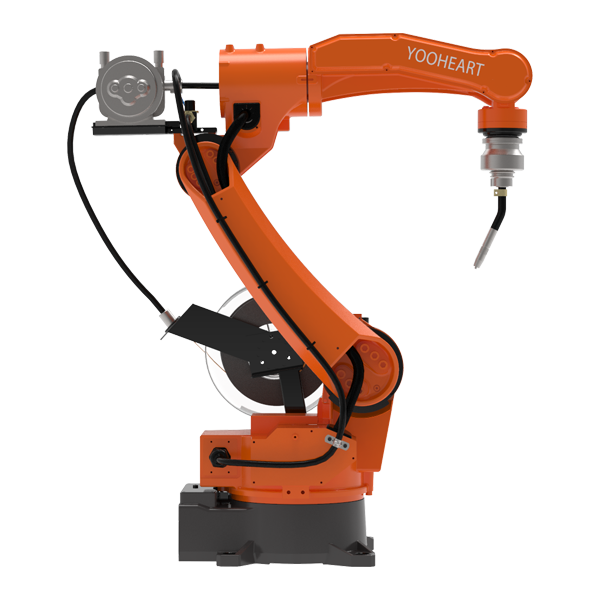

HOTO NA 1

Gabatarwa

Tig welding robot don Electric Iron

Pulse Tig walda tsarin don kifin sikelin weld dinki.

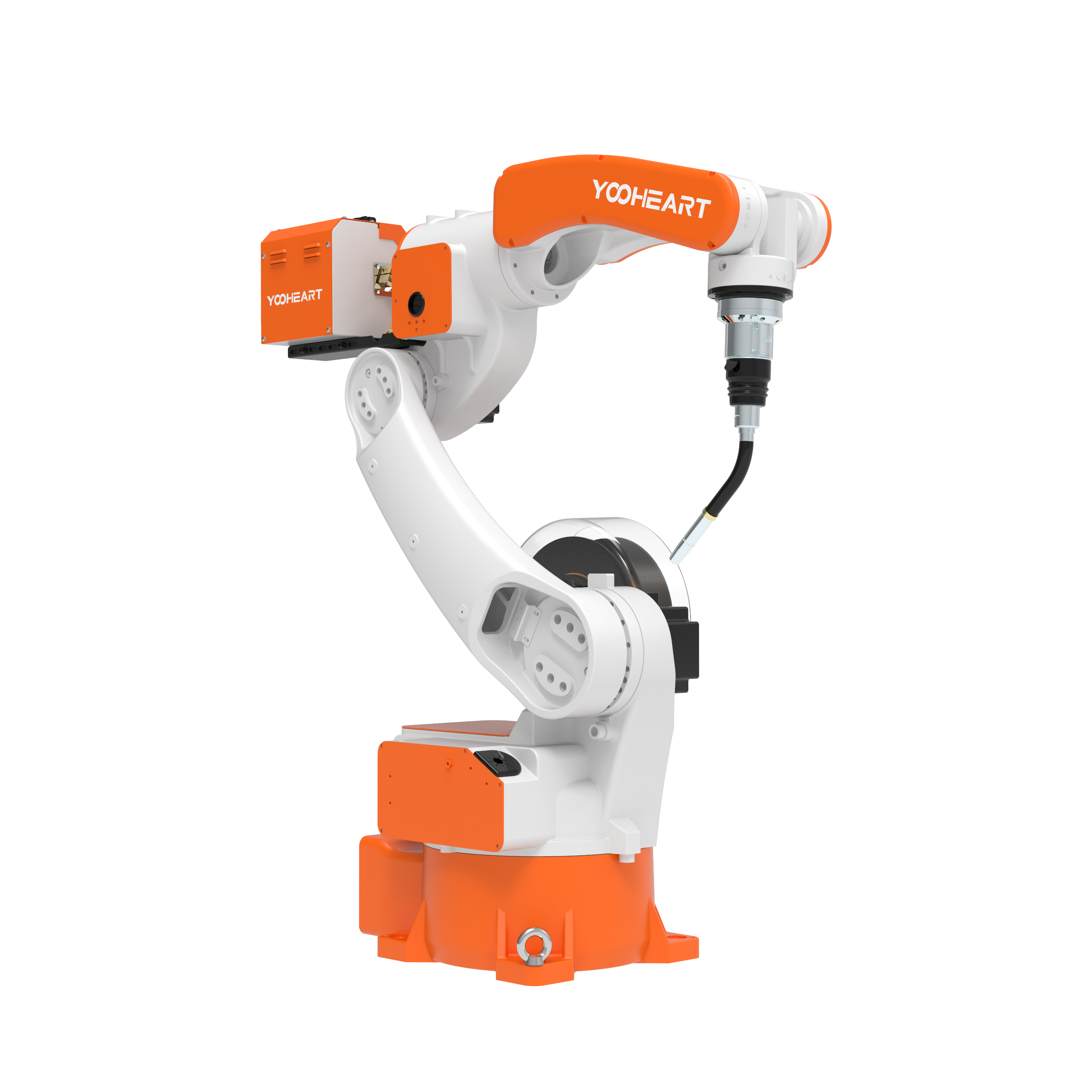

HOTO NA 2

Gabatarwa

Tig welding robot don Bakin Karfe

Tig arc waldi don square bututu waldi.

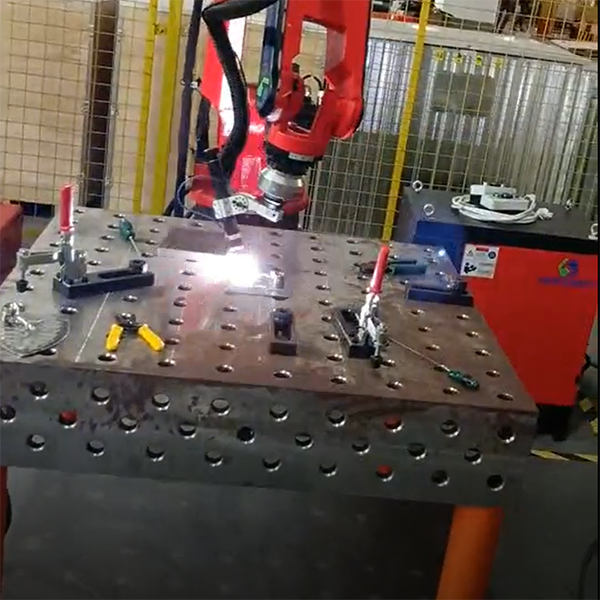

HOTO NA 3

Gabatarwa

Siga na TIG walda walda

Pulse Tig walda wasan kwaikwayo. Kauri: 1.5mm, Kuskuren dacewa: ± 0.2mm.

ISAR DA KASAR

Yunhua na iya ba abokan ciniki da sharuɗɗan bayarwa daban-daban. Abokan ciniki za su iya zaɓar hanyar jigilar kaya ta teku ko ta iska bisa ga fifikon gaggawa. YOO HEART marufi na robot na iya saduwa da buƙatun sufurin ruwa da iska. Za mu shirya duk fayiloli kamar PL, takardar shaidar asali, daftari da sauran fayiloli. Akwai ma'aikaci wanda babban aikinsa shi ne tabbatar da cewa kowane mutum-mutumi za a iya isar da shi zuwa tashar jiragen ruwa na abokan ciniki ba tare da tsangwama ba a cikin kwanaki 40 na aiki.

Bayan sabis na siyarwa

Ya kamata kowane abokin ciniki ya san robot ɗin YOO HEART mai kyau kafin su saya. Da zarar abokan ciniki sun sami robot ɗin YOO HEART guda ɗaya, ma'aikacin su zai sami horo na kwanaki 3-5 kyauta a masana'antar YOO HEART. Za'a samu group ko WhatsApp group, ma'aikatanmu da suke da alhakin bayan sale service, Electric, Hardware, software da dai sauransu, idan matsala daya ta faru sau biyu, ma'aikacin mu zai je wurin abokan ciniki don magance matsalar.

FQA

Q1. Menene mafi kyawun aikace-aikace don tsarin walda TIG na robotic?

A.High-girma, ƙananan aikace-aikace iri-iri sun dace da walƙiya na robotic; duk da haka, ƙananan ƙira, aikace-aikace iri-iri na iya aiki idan an aiwatar da kayan aiki masu dacewa. Kamfanoni za su buƙaci yin la'akari da ƙarin farashi don kayan aiki don sanin ko tsarin walda na mutum-mutumi zai iya samar da tabbataccen dawowa kan saka hannun jari na farko. Amma ga TIG waldi, mafi kyawun aikace-aikacen shine yanki na bakin ciki da ƙarfe.

Q2. Wanne yafi amfani? HF TIG waldi ko ɗaga TIG waldi?

A. Mafi mashahuri kuma mafi kyawun zaɓi shine amfani da Matsakaicin farawa wanda ke haifar da babban mitar arc wanda ke da ikon ionizing iska da daidaita rata tsakanin ma'anar tungsten da yanki na aiki. Mafarkin Maɗaukakin Maɗaukaki hanya ce marar taɓawa kuma yana haifar da kusan gurɓata sai dai idan tungsten ya ƙare sosai ko kuma amperage ya yi tsayi da yawa a farkon. Yana da kyakkyawan zaɓi don walda aluminum, kuma hakika shine kawai zaɓi mai karɓa. Sai dai idan kuna buƙatar walda Aluminum, ba lallai ne ku sami farkon farawa mai girma ba, amma yana da kyau a sami AC ko DC idan kuna da zaɓi.

Q3. Shin YOO HEART TIG robot waldi zai iya amfani da filler?

A. Ee, muna ɗaya daga cikin ƴan kaɗan waɗanda za su iya amfani da filler lokacin waldawar TIG. Yawancin masu samar da kayayyaki a kasuwa na iya gaya muku cewa ana iya amfani da robots ɗin su don waldawar TIG, kuna iya tambayarsa tambayoyi kamar: yadda ake tace HF?

Q4. Yadda ake saita tushen wuta yayin amfani da walda na TIG?

A.Ya kamata a saita na'urar waldawar ku zuwa DCEN (Direct current electrode negative) wanda kuma aka sani da madaidaiciyar polarity ga kowane yanki na aiki da ke buƙatar waldawa sai dai idan kayan sun kasance ko dai aluminum ko magnesium. An saita babban mita don farawa wanda aka samo shi an gina shi a zamanin yau a cikin inverters. Ya kamata a saita kwararan bayan gida aƙalla mafi ƙarancin daƙiƙa 10. Idan A/C yana nan an saita shi zuwa saitin tsoho wanda yayi daidai da DCEN. Saita mai tuntuɓar mai tuntuɓar da amperage zuwa saitunan nesa. Idan kayan da ake buƙatar waldawa shine polarity na aluminum yakamata a saita shi zuwa A/C, yakamata a saita ma'aunin A/C zuwa kusan 7 kuma ya kamata a ci gaba da samar da mitar mai girma.

Q5. Yadda za a saita garkuwa Gas a lokacin walda TIG?

A. TIG waldi yana amfani da iskar gas maras amfani don kare yankin waldawa daga gurɓatawa. Don haka ana kuma bayyana wannan iskar gas ɗin a matsayin iskar kariya. A kowane hali yakamata ya zama argon kuma babu sauran iskar gas kamar Neon ko xenon da sauransu musamman idan ana son yin walda ta TIG. Ya kamata a saita a kusa da 15 cfh. Don walda aluminum kawai zaka iya amfani da haɗin 50/50 na argon da helium.