Robotic Mig waldi ---- Titin Lamp Pole waldi mafita

Fihirisa

1. Bayanin kayan aiki

2. Bayanin Maganin walda na Robotic

3. Tsarin Magani na walda na Robotic

4. Kanfigareshan Magani na Robotic

5. Babban Aiki 6. Gabatarwar Kayan Aiki

7. Shigarwa, Gudanarwa da Horarwa

8. Dubawa da Karɓa

9. Abubuwan Bukatun Muhalli

10. Garanti da Bayan tallace-tallace sabis

11. Bayarwa Haɗe Takardu

Bidiyo Application na walda

1, Bayanan Aiki

-Diamita Wayar Weldingku: 1.2mm

-Tsarin walda: walda mai kariya / Mig waldi

-Weld dinka irinNau'in layi madaidaiciya, Nau'in Circle

-Garkuwar iskar gas:99% CO2

-Hanyar Aiki: loading da saukewa da hannu, walda ta atomatik

-Kuskuren daidaitawa:0.5mm diamita

-Tsabtace faranti :ƙarfe luster za a iya gani a cikin weld daa cikin kewayon sau biyu tsawo na weld kabu a garesu

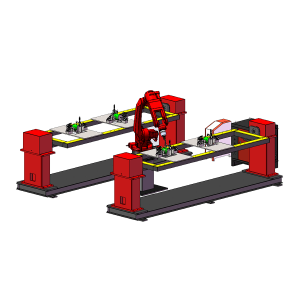

2, Robotic welding Solution Overview

Don inganta ingantaccen aiki, bisa ga ainihin halin da ake ciki na kayan aiki, masana'antar Honyen za ta samar da saiti na aikin mutum-mutumi na walda, wanda za'a iya maye gurbinsa da kayan aiki daban-daban don dacewa da samfuran daban-daban.Wurin aiki yana kunshe da samfurin robot: HY1006A-145 robot waldi, tushen wutar lantarki, fitilar walda ta musamman don robot, majalisar kula da wutar lantarki da maɓalli, mai sanyaya ruwa mai sanyaya ruwa, ma'aikatan tashar aiki sau biyu, kayan aikin kayan aiki, shingen kariya aminci (na zaɓi) da sauran su. sassa.

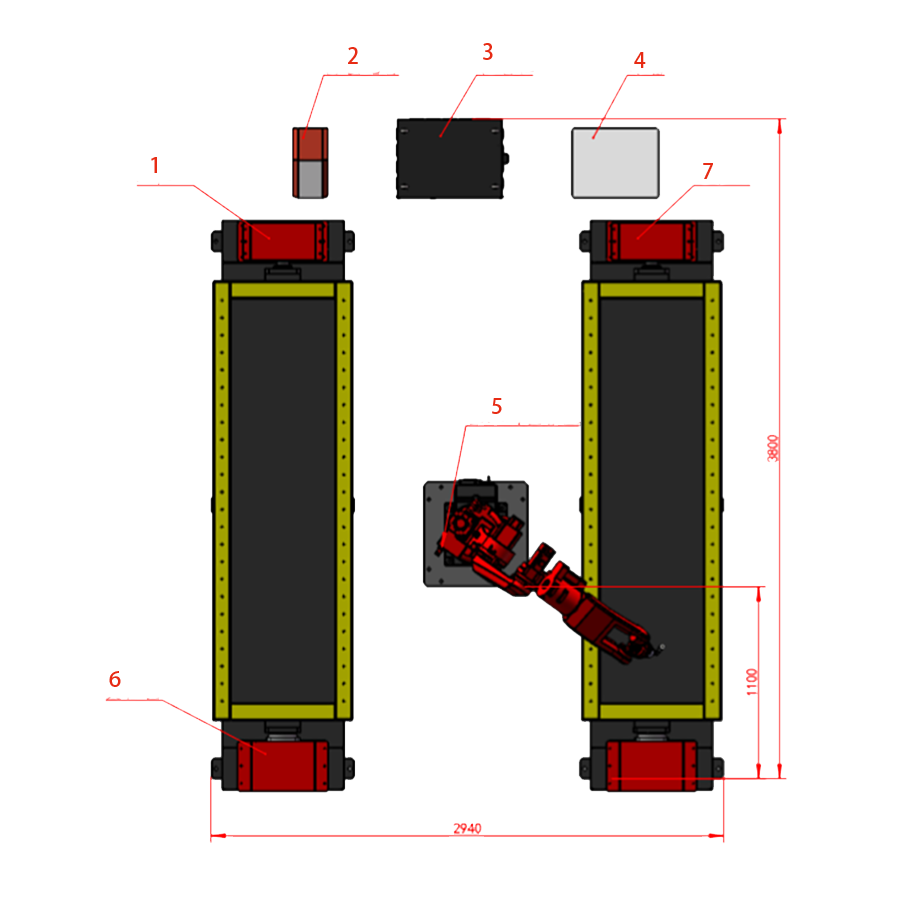

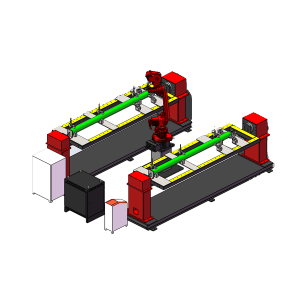

3, Mig Welding mutummutumi aiki shimfidar wuri gabatarwa

Tsarin aikin walda na Honyen robot Arc

1, Tashar aiki 1

2, Welding Power source

3, Mai sarrafa Robot

4, Mai sanyaya ruwa

5, Robot waldi na Honyen, HY1006A-145

6, Mai matsayi

7, Tashar aiki 2

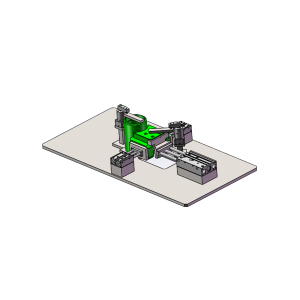

Wutar lantarki sassa kayan aiki

Kayan aikin sandar wutan lantarki 2

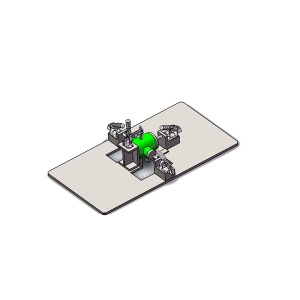

Maganin walda na Robotic Layout 1

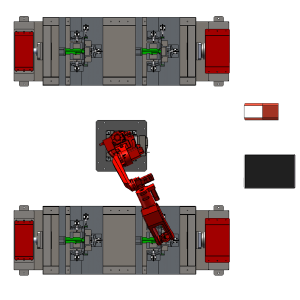

Abubuwan Gyaran Wuta na Wuta Lantarki 3

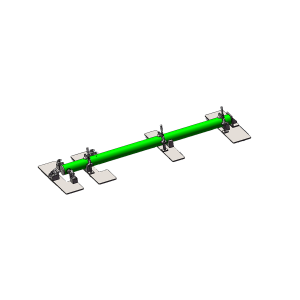

Layout na Robotic Welding Solutions 2

Layout na Robotic Welding Solutions 3

4. Tsarin Magani na walda na Robotic I. Mai aiki yana loda kayan aiki a tashar 1, Bayan lodawa da matse shi.Mai aiki yana danna maɓallin farawa na ajiyar mutum-mutumi 1, kuma mutum-mutumi ya fara walƙiya ta atomatik;

II.Operator yana zuwa tashar 2 don loda kayan aiki.Bayan loading workpiece, Operator latsa robobi ajiyar wuri button 2 da kuma jiran robot gama waldi;

III.Bayan robot ya gama walda a tashar 1, ta atomatik yana aiwatar da shirin tashar 2;

Ⅳ.Sannan Operator ya sauke Workpiece a tashar 1 kuma ya loda sabon kayan aiki;

V. zagayowar a jere.

5. Kanfigareshan Magani na Robotic

| Abu | Samfura | Yawan | Alamar | Jawabi | ||

| 1 | 1.1 | Robot jiki | HY1006A-145 | 1 Saita | zuma | Ciki har da jikin mutum-mutumi, majalisar kulawa, mai tsara shirye-shiryen koyarwa |

| 1.2 | Robot iko majalisar | 1 saiti | ||||

| 1.3 | Welding Power Source | 1 Saita | zuma | Megmeet walda | ||

| 1.4 | tankin ruwa | 1 Saita | zuma | |||

| 1.5 | Wutar walda mai sanyaya ruwa | 1 Saita | zuma | |||

| 2 | 1 Matsayin axis | HY4030 | 2 Saita | zuma | 2.5m, 300kg lodi, 1.5KW rated fitarwa ikon | |

| 3 | Tashar sarrafa wutar lantarki | 2 Saita | zuma | |||

| 4 | Tsarin tsarin, haɗin kai da shirye-shirye | 1 Saita | zuma | |||

| 5 | Katangar tsaro | 1 Saita | zuma | Na zaɓi | ||

6. Babban Aiki Domin tabbatar da ingancin walda da inganci, tsarin mutum-mutumi yana sanye da cikakken aikin kare kai da bayanan walda na baka.Manyan ayyuka sune kamar haka:

Ci gaba da hanyar asali: lokacin da garkuwar iskar gas ba ta da kyau, wayar walda tana cinyewa kuma ta tsaya na ɗan lokaci yayin walda, ana iya kiran umarnin "ci gaba da walda" kai tsaye bayan an warware matsalar, kuma robot na iya ci gaba da walda kai tsaye daga kowane matsayi zuwa matsayin da aka dakatar.

Gano kuskure da tsinkaya: bayan ƙararrawa ya faru, Robot yana samun bayanai daga na'urar sarrafawa, ƙididdige ɓangarori na kuskure, kuma ya ba da jerin manyan ɓangarori na ɓarna, nuna jerin abubuwan maye gurbin da ganewar asali akan kwamfuta, waɗanda za'a iya kallo akan shafin tare da lanƙwasa koyarwa.Bugu da kari, kwamfuta akai-akai Samun bayanan aiki daga mutum-mutumi, bincikar bayanan da aka samu, yin hukunci ko yanayin aikin mutum-mutumi ya saba, da kuma sa mai amfani da shi don magance kuskuren da ke tafe.

Ayyukan rigakafin karo: lokacin da fitilar waldawar mutum-mutumi ta yi karo da wasu abubuwa na waje, na'urar rigakafin karo na robot tana aiki don kare Torch ɗin walda da jikin mutum-mutumi.

Ƙwararrun bayanai: ta hanyar saita yanayin walda masu dacewa a cikin shirin, wannan tsarin zai iya kammala tsari ta atomatik na suturar walda da daidaita daidaitattun sigogin walda.

Koyarwa da shirye-shirye: gane shirye-shirye a kan-site ta hanyar koyarwa abin lanƙwasa.

Saƙa waldi: a lokacin walda tsari, Robot ba zai iya kawai gane na kowa lilo waldi zagaye irin da kuma Z irin.Wannan yana taimaka robot fahimtar aikin walda na abokin ciniki bisa ga sifar yanki, don haɓaka girman kabu tare da ƙarfin walda da kyakkyawan aikin walda.

Nuna matsayi: mutum-mutumi na iya nuna matsayin aiki na duk tsarin robot ta hanyar abin wuyan koyarwa, gami da matsayin aikin shirin, canje-canjen tsarin walda, canjin tsarin tsarin, matsayi na yanzu na robot, rikodin tarihin kisa, alamun aminci, rikodin ƙararrawa, da sauransu, don abokan ciniki su iya. daidai lokacin fahimtar matsayin tsarin robot kuma hana matsaloli a gaba.

Fayilolin shigarwa / fitarwa: fayilolin tsarin mutum-mutumi da fayilolin shirin a cikin tsarin robot ana iya adana su a cikin katin SD a cikin mai sarrafa Robot, kuma ana iya adana su zuwa kayan aiki na waje.Shirye-shiryen da aka rubuta ta software na shirye-shiryen layi kuma za a iya loda su cikin mai sarrafa Robot, Wannan yana taimaka wa abokan ciniki su adana fayilolin tsarin akai-akai, Da zarar an sami matsala a cikin tsarin mutum-mutumi, ana iya dawo da waɗannan madadin don magance matsalolin robot.

7, Gabatarwar Kayan Aiki HY1006A-145 babban mutum-mutumi ne mai aiki da hankali.Ya dace da walƙiya garkuwar gas da aikace-aikacen yankewa.Siffofin sa nauyi ne mai sauƙi da ƙaramin tsari.

Don aikace-aikacen walda na baka, Honyen ya sami nasarar tsara nauyin nauyi da ƙaramin hannu, wanda ba wai kawai yana tabbatar da amincin asali ba, kuma yana fahimtar kyakkyawan aikin farashi.

Honyen yana amfani da fasahar servo mafi ci gaba, wanda zai iya inganta saurin motsi da daidaiton mutum-mutumi, rage sa hannun ma'aikaci, da haɓaka ingantaccen aiki don walda da yanke garkuwar gas.

| Axis | Kayan aiki | Maimaituwa | Ƙarfin wutar lantarki | Muhalli | Nauyi | Shigarwa |

| 6 | 10 | 0.08 | 6.5KVA | 0 ~ 45 ℃20 ~ 80% RH (Babu Humidity) | 300kg | Kasa/Rufi |

| Rage Motsi J1 | J2 | J3 | J4 | J5 | J6 | IP matakin |

| ± 170° | + 80 ° ~ -150 ° | +95°~-72° | ± 170° | + 115 ° ~ -140 ° | ± 220° | IP54/IP65( wuyan hannu) |

| Babban gudun J1 | J2 | J3 | J4 | J5 | J6 | |

| 158°/s | 145°/s | 140°/s | 217°/s | 172°/s | 500°/s |

Cikakken tsarin aikin Sinanci kuma ana iya canza shi zuwa Ingilishi tare da cikakken aikin madannai

Goyan bayan hanyoyin sadarwa daban-daban ciki har da I / O interface, Modbus, Ethernet da sauransu.

Taimakawa haɗin kai tare da mutummutumi da yawa da sauran kayan aikin waje

Babban girman allo mai launi mai launi

Saita na'urar rigakafin karo, kare hannun mutum-mutumi da rage tsangwama

Ikon Motsi na Robot yana ba da mafi kyawun tsara hanya

Daruruwan ginanniyar jakunkuna da ayyuka suna sauƙaƙe shirye-shirye

Ta hanyar katin SD, ya dace don adanawa da kwafi bayanai

Mai matsayi

Honyen Head-tail biyu goyon bayan positioner wanda ake amfani dashi don juya workpiece, yin aiki tare da robot, kai matsayi mai kyau don walda da cimma kyakkyawan aikin walda.

Welding Power source

Megmeet Ehave cm 500h / 500/350 jerin cikakken kayan aikin masana'antu na dijital * CO2 / MAG / MMA na'urar walda mai hankali

8. Shigarwa, Gudanarwa da Horarwa

Kafin bayarwa, tsarin robot ɗin za a haɗa shi kuma a gwada cikakken aiki a cikin kamfaninmu.Abokin ciniki zai isar da sassan su ga kamfaninmu don walƙiya na gwaji da karɓa kafin bayarwa.A lokacin karɓuwa, ma'aikatan Abokin ciniki za su sami horon fasaha na farko.

Za a ƙaddamar da shirin shigarwa da buƙatun fasaha ga abokin ciniki kwanaki 15 kafin shigarwa, kuma abokin ciniki zai yi shirye-shirye na lokaci bisa ga buƙatun.Kamfaninmu zai aika injiniyoyi don aiwatar da shigarwa da ƙaddamar da tsarin a rukunin yanar gizon mai amfani.A ƙarƙashin yanayin cewa abokin ciniki yana tabbatar da isassun kayan aikin kwamishinoni, lokacin daga ƙaddamar da shirye-shirye, horar da ma'aikata don samar da gwaji da yawa ba zai wuce kwanaki 10 ba.Kamfaninmu yana horar da masu amfani da tsarin tsarin mutum-mutumi, aiki da kula da abokan ciniki, kuma masu horarwa yakamata su kasance da ainihin ilimin kwamfuta.

A lokacin shigarwa da ƙaddamarwa, abokin ciniki zai samar da kayan aiki masu mahimmanci, kamar kayan aiki na ɗagawa, cokali mai yatsa, igiyoyi, rawar tasiri, da dai sauransu, da kuma ba da taimako na wucin gadi yayin saukewa da shigarwa.

Kamfaninmu yana da alhakin jagora, shigarwa, ƙaddamar da kayan aiki da horar da ma'aikata.Kamfaninmu yana da alhakin kulawa da horar da aiki.Mai aiki zai yi aiki da kuma kula da kayan aikin da kansu.Abubuwan da ke cikin horo: ƙa'idar tsarin kayan aiki, matsala na lantarki gama gari, gabatarwa ga ƙa'idodin shirye-shirye na asali, ƙwarewar shirye-shirye da hanyoyin shirye-shirye na sassa na yau da kullun, gabatarwa da matakan kariya na kwamitin aikin kayan aiki, aikin aikin kayan aiki, da sauransu.

9. Dubawa da karɓa

Ana aiwatar da karɓar karɓa a cikin kamfaninmu tare da haɗin gwiwar ma'aikatan da suka dace na bangarorin biyu.A lokacin karɓan farko, za a gwada kayan aikin bisa ga daidaiton kayan aikin da abokin ciniki ya bayar, ƙwararren ƙwararren aikin kawai za a yi walda, kuma za a ba da rahoton gwajin yarda da kai.Bayan kammala karba, za a isar da Robot.Don tabbatar da yarda da karɓa, za a ba da kayan aikin 3 don samar da al'ada.

10.Bukatun Muhalli Bukatun aminci: iskar gas da kayan gyara da masu amfani ke amfani da su dole ne su bi ka'idodin ƙasa masu dacewa.

Dole ne a saita tushen iska a waje, ba ƙasa da 15m nesa da wuta ba, kuma ba ƙasa da 15m nesa da iskar gas da iskar oxygen ba.Tushen iska zai kula da kyakkyawan yanayin samun iska kuma ya kasance a wuri mai sanyi nesa da iska.

Dole ne a duba duk hanyoyin da'irori na iskar gas kafin amfani da robot.Idan akwai zubar iska, dole ne a gyara shi don tabbatar da cewa babu kuskure.

lokacin daidaita matsa lamba da canza silinda gas, mai aiki ba zai sami abubuwan mai a hannunsa ba.

zafi na yanayi: gabaɗaya, zafi na yanayi shine 20% ~ 75% RH (idan babu condensation);Gajeren lokaci (a cikin wata 1) ƙasa da 95% RH (lokuta ba tare da tari ba).

matsa iska: 4.5 ~ 6.0 kgf / cm2 (0.45-0.6mpa), tace mai da ruwa, ≥ 100L / min

Foundation: ƙaramin ƙarfin kankare shine C25, kuma ƙaramin kauri na tushe shine 400 mm

girgiza: nisantar tushen jijjiga

wutar lantarki: samar da wutar lantarki na duk kayan aikin lantarki da na lantarki da aka kera suna ɗaukar 50Hz (± 1) da 380V (± 10%) ƙarfin wutar lantarki na AC uku don tabbatar da ƙasa na farko na samar da wutar lantarki.

Akan sabis ɗin da abokan ciniki ke bayarwa:

duk shirye-shiryen da ake buƙata kafin bayarwa, kamar tushe, aikin walda mai mahimmanci, gyara kayan aikin taimako, da sauransu.

saukewa da sufuri a wurin abokin ciniki.

11. Garanti da Bayan tallace-tallace sabis Lokacin garanti na tushen wutar lantarki shine watanni 12.

Lokacin garanti na jikin mutum-mutumi shine watanni 18.

Idan akwai gazawa ko lalacewa a ƙarƙashin amfani na yau da kullun kuma kayan aikin yana cikin lokacin garanti, kamfaninmu na iya gyara ko maye gurbin sassa kyauta EXW (ban da abubuwan amfani, samfuran kiyayewa, bututun aminci, fitilun nuni da sauran abubuwan da aka keɓance musamman ta kamfaninmu).

Don sassa masu rauni ba tare da garanti ba, kamfaninmu yayi alƙawarin rayuwar sabis na yau da kullun da farashin wadatar kayan sassa masu rauni, kuma kayan aiki yana da ingantaccen tashar samar da kayan aiki har zuwa shekaru biyar.

Bayan lokacin garanti, kamfaninmu zai ci gaba da ba da sabis na biyan kuɗi na tsawon rai da kuma samar da cikakken goyon bayan fasaha da kayan haɗi da ake buƙata.

12. Bayarwa Haɗe Takardu Zane-zane na shigarwa: kayan aikin ginin gine-gine da zane-zane na kayan aiki

◆ zane zane: kayan aiki da kayan aiki

◆ Manual: manual aiki manual, tabbatarwa manual da robot aiki manual

◆ kayan haɗi: lissafin bayarwa, takaddun shaida da katin garanti.